This week we explore the origin story of distressed denim, how it’s made and its best iterations.

Origins of Distressed Denim

Legend has it that a 1970 Ian Tyas photograph of British artist and activist Caroline Coon, wearing patched jeans with a scarf tied at her waist, is responsible for inspiring a generation of designers to create distressed denim.

Others attribute its popularity to 1975 when the punk movement exploded across the United States, Great Britain and Australia. In the U.S., punk was inextricable from the literary rock scene based around Manhattan’s CBGB, where the Patti Smith Group and Television performed.

Around the same time, industry disruptors Adriano Goldschmied and François Girbaud began experimenting with ways to transform denim in the wash — the latter throwing skateboard wheels and beach sand into dryers to achieve the perfect finish.

In the ‘80s, Renzo Rosso, Diesel’s founder, sent a box of distressed denim to retailers in Japan, who sent the jeans back. They thought Renzo had sent them used merchandise. Today’s Creative Director at Diesel, Glen Martens, explains that distressed jeans “symbolize disruption, empower the wearer and allow for the individualization of a core style.”

How It’s Made

For some, buying raw denim and wearing the jeans into oblivion, earning natural rips and tears along the way, is a right of passage. In the ’60s, it was not uncommon to see “shrink to fit” styles worn while swimming in the ocean, to achieve the perfect salt-washed finished. For others, the thought of breaking in stiff denim over the course of a decade sounds like a nightmare. That’s why denim companies have developed complex and hyper specialized methods for distressing jeans.

In the early days, companies used sandblasting and pumice stone-tumbling in their production practices. After learning about the harmful effects of these methods on both people and the planet, many companies today employ hand sanding and lasers, which burn whiskers and holes into jeans without using any water.

Lasers

In recent years, laser technology has grown tremendously. A laser beam can create virtually any wash pattern. Because no water or chemicals are used in the process, this is a much more environmentally conscious practice.

Hand Sanding

Trained craftspeople use sandpaper and sanding blocks to abrade the denim and remove layers of color. Sometimes, they use a mold to create the appearance of creases. It is a much more expensive process as new molds are created for every wash.

Meet Your Match

In today’s market, there is a wide range of meticulously crafted denim finishes and washes to choose from. Explore our offering of denim from Japan, Germany, Brazil, the U.S. and Italy.

Dark Denim

Preserving the look of raw or untreated denim, these styles allow for more movement than their untreated counterparts.

Light Touch Denim

With much of the original stitching and indigo intact, these styles offer a slightly lived-in look — while still suiting a classic sensibility.

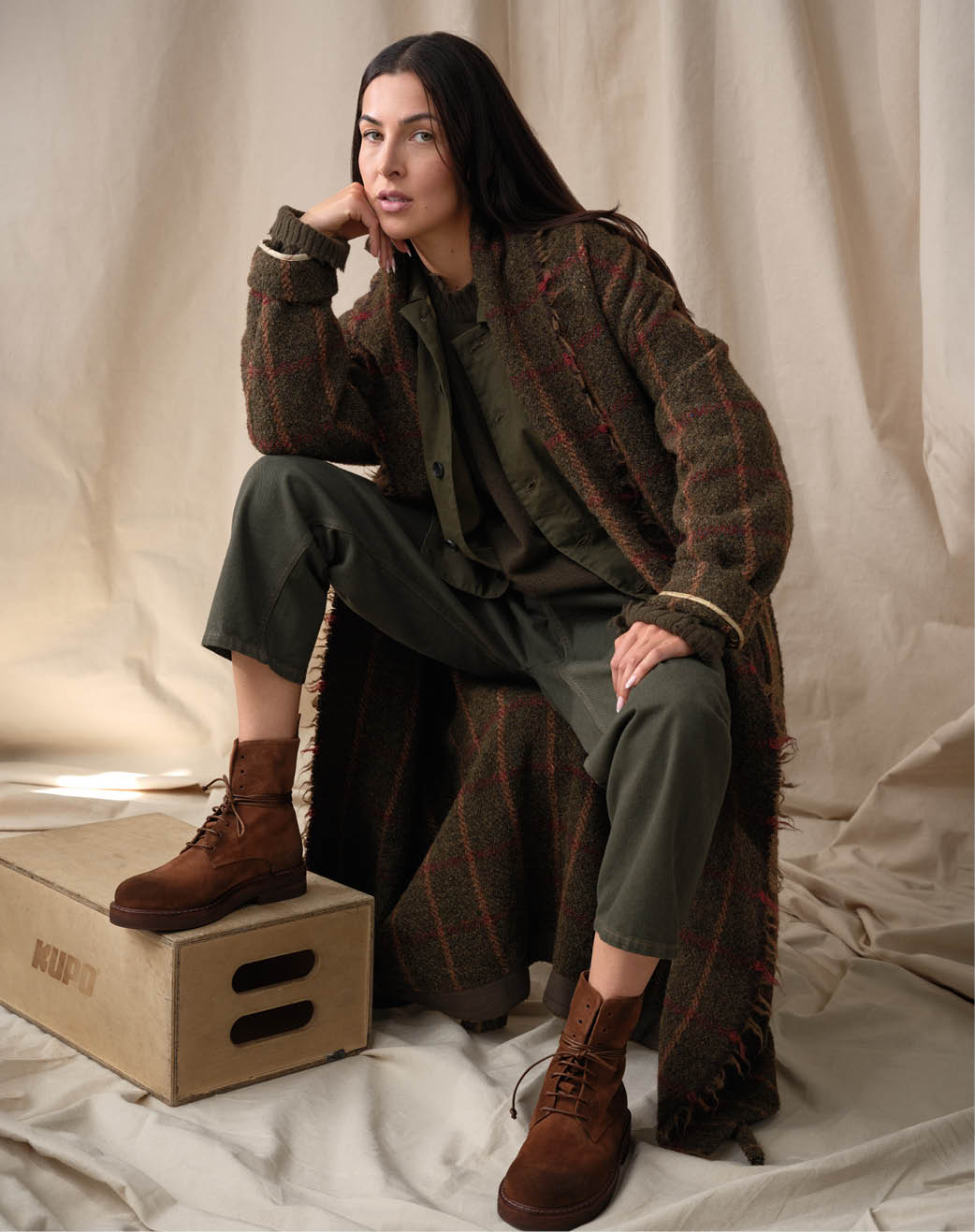

Lived-In Denim

Celebrating the patina of wear-on-repeat denim, these styles offer both endless comfort and an unmatched cool factor.