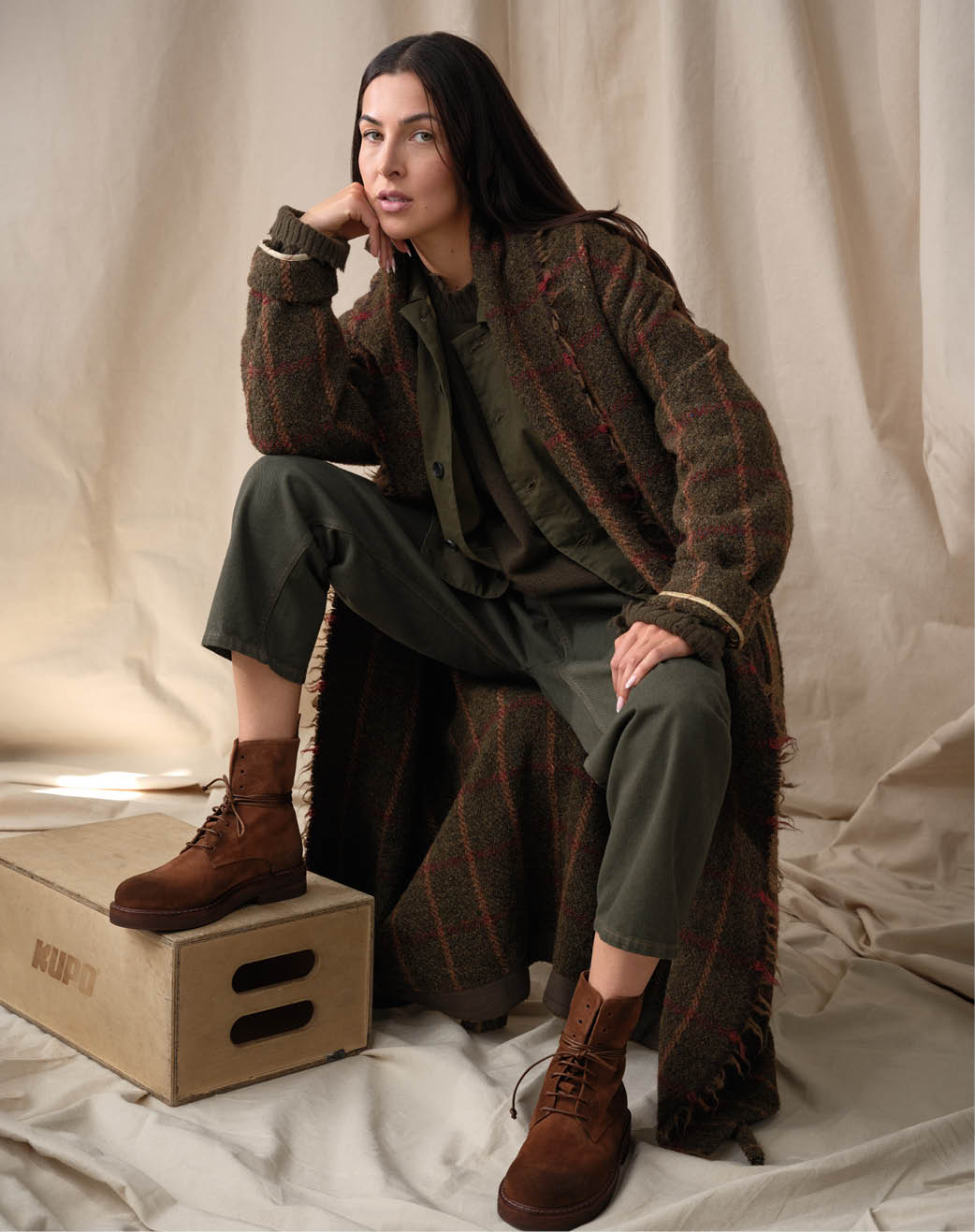

Leather bags, like the ones offered by Massimo Palomba, are a delight to have and to hold. The supple texture, beautiful color and superior craftsmanship create an accessory that will stand the test of time, stylistically and literally.

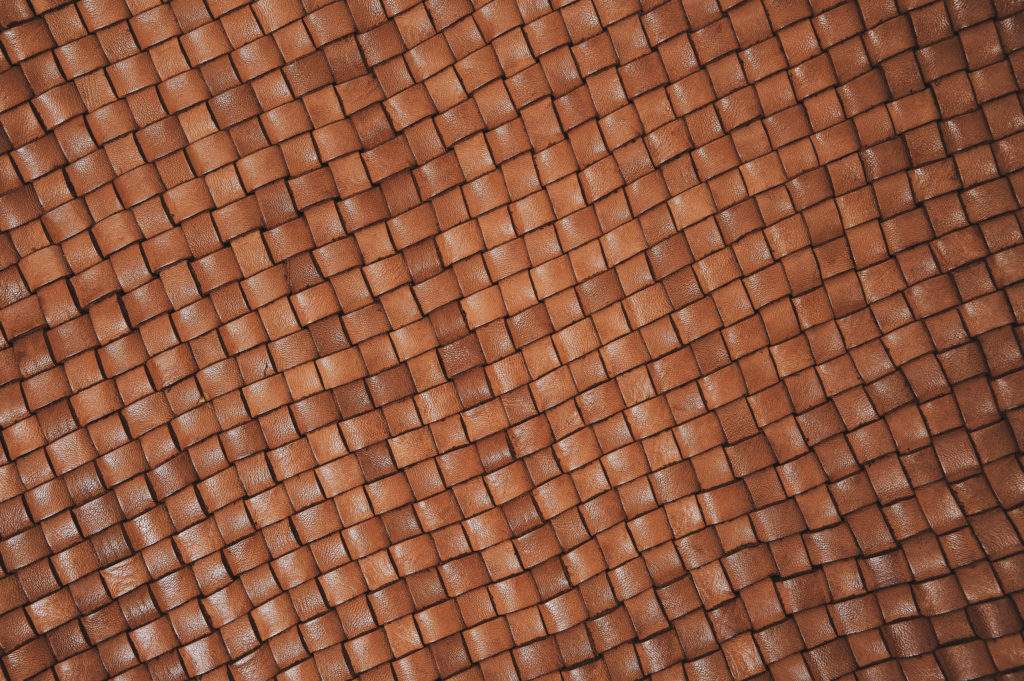

In warmer weather, we look forward to the basket weave of summer handbags. While admiring the delicate interlacing of leather strands, one cannot help but think about the detail and hard work that goes into creating such a beautiful thing. While woven leather bags are indeed a labor of love, their multi-functionality and almost meditative pattern make them a delight to create.

Artisans will start by designing what they would like the bag to look like and how it will be woven. Leather weaving is a time consuming process and planning ahead to avoid any weakness in the bag is key. They then choose the leather to make the bag. They look for strength in fiber and richness in color. Leather is dyed before this process begins using a variety of natural dyes and colorants to produce the rich color designers like Campomaggi and Massimo Palomba are known for.

The leather is then bisected into many even strands, three to four times longer than the bag itself will be. The artisan sets about interlacing the strands together at what will be the top of the bag, adding strands of leather as they make their way around the opening to create the border. Often, this weaving is done around a wooden mold for the bag as a guide and structure for the weaving. This mold informs the size, shape and style of the bag. As they move through their pattern, layering strands of leather together to create the texture, they pull tightly on the strands to ensure strength and fastness.

After the body of the bag has been woven, the artisan will attach the leather handles and stamp in their signature. Designers like Massimo Palomba will add custom casted hardware like rivets or rings. Creating bags like this can take the artisan up to 35 hours to complete, but the end result is an accessory timeless and unique.